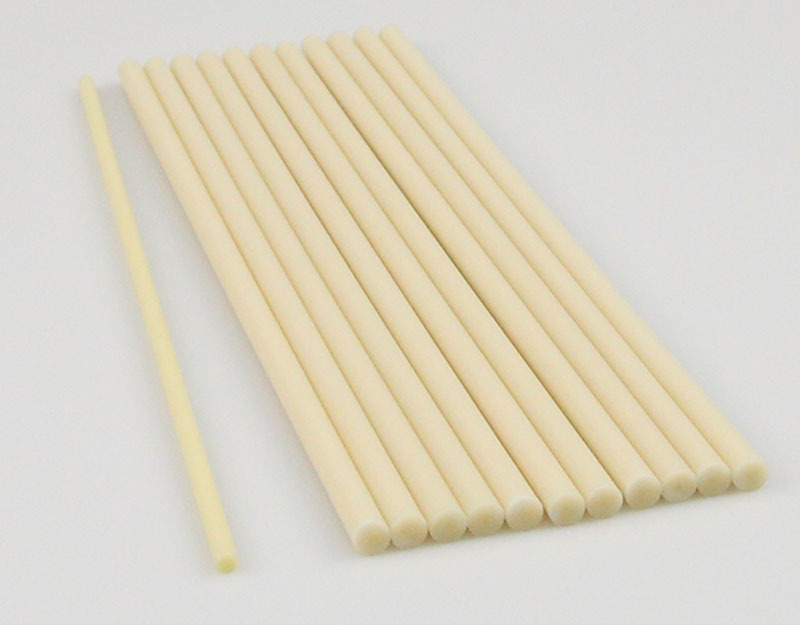

Shrink tube

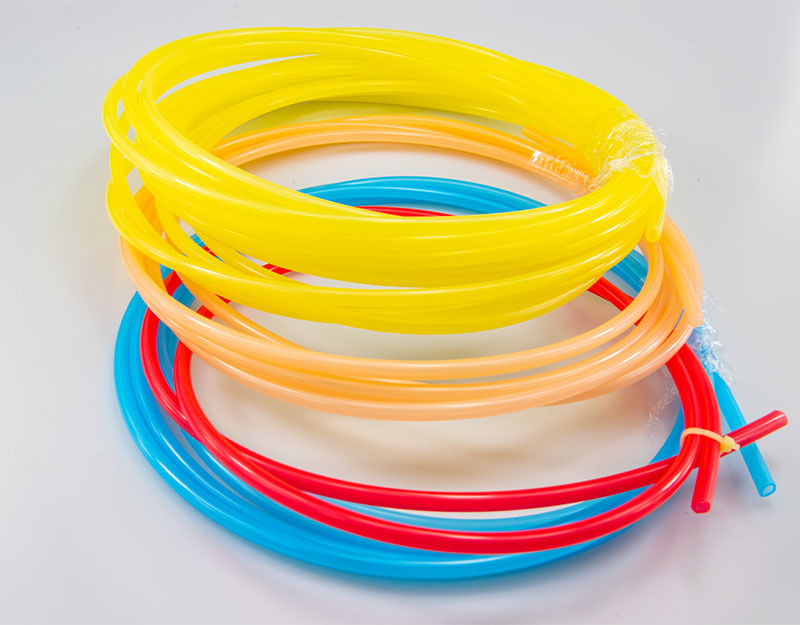

Communication cold shrink tubes use silicone rubber as raw material, pre-expanded on a retractable support tube, and shrink under normal temperature by elastic retraction. They also have an inner lining clay process, increasing the product's sealing performance. They have the advantages of insulation, sealing, protection, small size, convenient and quick operation, no need for special tools, and wide applicability. Compared with heat shrink products, they do not require tools for heating and can be tightly sealed even under thermal expansion and contraction, without gaps caused by thermal expansion and contraction.

Keywords:

Shrink tube

Category:

Hotline:

Email:

Shrink tube

Communication cold-shrink tubes use silicone rubber as raw material, pre-expanded on a retractable support tube, and contract at room temperature by elastic recoil. They also feature an inner clay lining process, increasing the product's sealing performance. They have the advantages of insulation, sealing, protection, small size, convenient and quick operation, no need for special tools, and wide applicability. Compared with heat-shrink products, they do not require tools for heating and can be tightly sealed even under thermal expansion and contraction, preventing gaps from forming due to thermal expansion and contraction.

Product Characteristics

1. Easy installation, only manual operation is required, no heating or special tools are needed, and no hot melt adhesive or tape is required to strengthen the seal at the joint;

2. Suitable for connecting and sealing cables of various specifications within a wide range, and can be used on power and communication cables in indoor, outdoor, overhead, underwater, or buried environments;

3. Strong resilience, large radial shrinkage force, small permanent deformation, even long-term use maintains a lasting radial pressure on the cable, ensuring tight sealing, and excellent moisture, water, and dust resistance;

4. Because EPDM has excellent resilience and "elastic memory," it can "breathe" with the seal, thus achieving excellent sealing performance. It maintains excellent sealing even in dynamic environments with wind-blown swaying;

5. Excellent resistance to salt spray corrosion, acids and alkalis, ozone aging, weather aging, and ultraviolet aging;

6. High mechanical strength, good softness, and excellent puncture resistance, abrasion resistance, bending resistance, and fatigue resistance.

Performance Parameters

| Item | Typical Value | Test Basis | |

| Material | Silicone Rubber | Ethylene Propylene Diene Monomer (EPDM) | - |

| Water Resistance | Excellent | Excellent | - |

| Protection Grade | IP67 | IP67 | IEC60529 |

| UV Resistance | Gray Scale Grade 3-4 | Gray Scale Grade 4 | ASTM G154 |

| Ozone Resistance | No Cracks | No Cracks | GB/T7762 |

| Mildew Resistance | Grade 0 | - | GB/T2423.16 |

| Hardness (Shore A) | 43 | 38 | GB/T531 |

| Tensile Strength (MPa) | 7.5 | 8 | GB/T528 |

| Elongation at Break (%) | 700 | 700 | GB/T528 |

| Tear Strength (kN/m) | 30 | 30 | GB/T529 |

| Volume Resistivity (Ω.cm) | 1x1015 | 1x1015 | GB/T1410 |

| Operating Environment | Indoor, Outdoor | Indoor, Outdoor | - |

Previous Page

Next Page

Previous Page

None

Next Page

Related Products

Consultation

Leave your contact information and we will contact you as soon as possible