Teflon heat shrink tubing

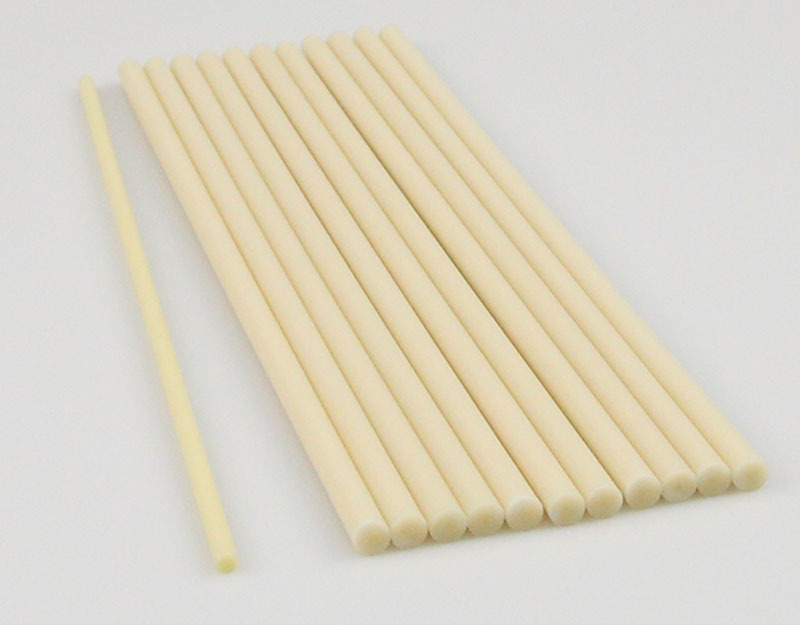

PTFE sleeves are made from imported high-quality polytetrafluoroethylene (PTFE, also known as Teflon or King of Plastics) resin through extrusion processing. This product has advantages such as high temperature resistance, high pressure resistance, corrosion resistance, wear resistance, and good self-lubrication. PTFE sleeves are widely used in various fields such as machinery, electronics, automobiles, aerospace, chemical industry, and communications.

Keywords:

Teflon heat shrink tubing

Category:

Hotline:

Email:

Teflon heat shrink tubing

PTFE tubing is made by extrusion processing of imported high-quality polytetrafluoroethylene (PTFE, also known as Teflon or "King of Plastics") resin. This product has advantages such as high temperature resistance, high pressure resistance, corrosion resistance, wear resistance, and good self-lubrication. High-temperature resistant (PTFE) tubing is widely used in various fields such as machinery, electronics, automobiles, aerospace, chemical industry, and communications.

Features

High and low temperature resistance; continuous operating temperature: -80℃ to +260℃

Corrosion resistance (resistant to strong acids, strong alkalis, chemical reagents, and oils)

Excellent electrical insulation: High voltage strength, effectively preventing leakage and short circuits, ensuring stable operation of electrical equipment.

Strong aging and weather resistance: The performance is stable and not easy to age under the long-term action of ultraviolet rays, ozone, high and low temperatures, and other environmental factors. It can be used outdoors or in harsh environments for a long time.

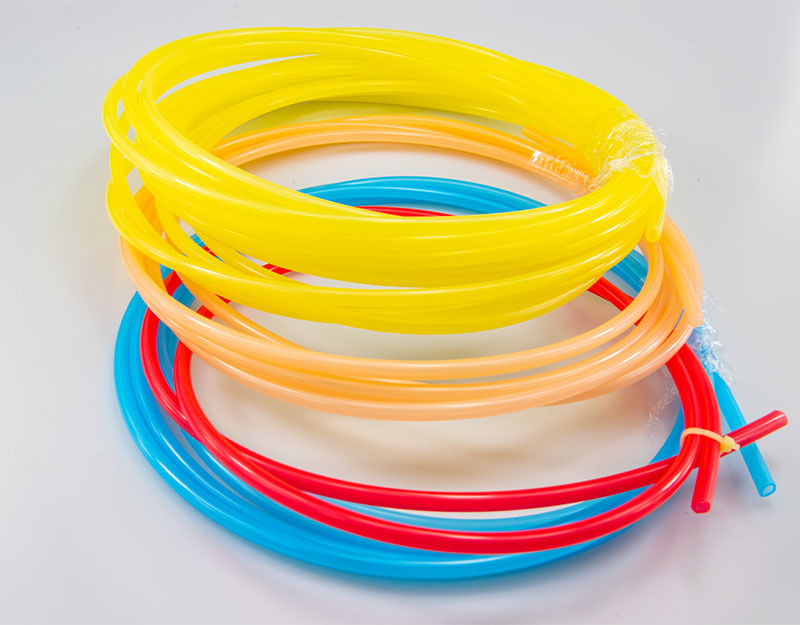

Standard Color: Transparent Clear

Performance Characteristics

| Item | Performance Parameters | Item | Performance Parameters |

| Relative Density | 2.14~2.20 | Continuous Operating Temperature | -80~ +260℃ |

| Tensile Strength (MPa) | ≥25 | Oxygen Index (%) | >90 |

| Tensile Yield Strength (MPa) | ≥11 | Water Absorption (%) | <0.01 |

| Elongation (%) | ≥300 | Coefficient of Linear Thermal Expansion (x105/℃) 21-100℃ | 10 |

| Arc Resistance | >300 | Breakdown Strength (kv/mm) | ≥26 |

| Shore Hardness (D) | 59-63 | Volume Resistivity (Ω.cm) | 1x1014 |

| Melting Point (℃) | 327℃ |

Specifications

Model AWG | Inner Diameter I.D (mm) | Outer Diameter O.D (mm)(S) | Outer Diameter O.D (mm)(T) | Outer Diameter O.D (mm)(L) | Standard Packaging (Meters/Reel) |

| 30 | 0.3±0.10 | 0.80±0.10 | 0.70±0.10 | 0.60±0.10 | 305 |

| 28 | 0.38±0.10 | 0.88±0.10 | 0.78±0.10 | 0.69±0.10 | 305 |

| 26 | 0.46±0.10 | 0.96±0.10 | 0.86±0.10 | 0.76±0.10 | 305 |

| 24 | 0.56±0.10 | 1.16±0.10 | 1.06±0.10 | 0.88±0.10 | 305 |

| 23 | 0.66±0.10 | 1.26±0.10 | 1.16±0.10 | 0.96±0.10 | 305 |

| 22 | 0.71±0.10 | 1.31±0.10 | 1.21±0.10 | 1.01±0.10 | 305 |

| 21 | 0.81±0.10 | 1.41±0.10 | 1.31±0.10 | 1.11±0.10 | 305 |

| 20 | 0.86±0.10 | 1.66±0.10 | 1.46±0.10 | 1.16±0.10 | 305 |

| 19 | 0.96±0.20 | 1.76±0.20 | 1.56±0.20 | 1.26±0.20 | 200 |

| 18 | 1.07±0.20 | 1.87±0.20 | 1.67±0.20 | 1.37±0.20 | 200 |

| 17 | 1.19±0.20 | 1.99±0.20 | 1.79±0.20 | 1.49±0.20 | 200 |

| 16 | 1.34±0.20 | 2.14±0.20 | 1.94±0.20 | 1.64±0.20 | 153 |

| 15 | 1.50±0.20 | 2.30±0.20 | 2.10±0.20 | 1.80±0.20 | 153 |

| 14 | 1.68±0.20 | 2.48±0.20 | 2.28±0.20 | 2.08±0.20 | 100 |

| 13 | 1.93±0.20 | 2.73±0.20 | 2.53±0.20 | 2.33±0.20 | 100 |

| 12 | 2.16±0.25 | 2.96±0.25 | 2.76±0.25 | 2.56±0.25 | 100 |

| 11 | 2.41±0.25 | 3.21±0.25 | 3.01±0.25 | 2.81±0.25 | 150 |

| 10 | 2.69±0.25 | 3.49±0.25 | 3.29±0.25 | 3.09±0.25 | 150 |

| 9 | 3.00±0.25 | 4.00±0.25 | 3.88±0.25 | 3.40±0.25 | 150 |

| 8 | 3.38±0.25 | 4.38±0.25 | 4.18±0.25 | 3.78±0.25 | 100 |

| 7 | 3.76±0.25 | 4.76±0.25 | 4.56±0.25 | 4.16±0.25 | 100 |

| 6 | 4.22±0.25 | 5.22±0.25 | 5.02±0.25 | 4.80±0.25 | 100 |

| 5 | 4.72±0.25 | 5.72±0.25 | 5.52±0.25 | 5.23±0.25 | 50 |

| 4 | 5.28±0.30 | 6.28±0.30 | 6.08±0.30 | 5.88±0.30 | 1.0M |

| 3 | 5.94±0.30 | 6.94±0.30 | 6.74±0.30 | 6.54±0.30 | 1.0M |

| 2 | 6.68±0.30 | 7.68±0.30 | 7.48±0.30 | 7.28±0.30 | 1.0M |

| 1 | 7.46±0.30 | 8.46±0.30 | 8.26±0.30 | 8.06±0.30 | 1.0M |

| 0 | 8.38±0.30 | 9.38±0.30 | 9.18±0.30 | 8.98±0.30 | 1.0M |

Previous Page

Next Page

Previous Page

None

Next Page

Related Products

Consultation

Leave your contact information and we will contact you as soon as possible