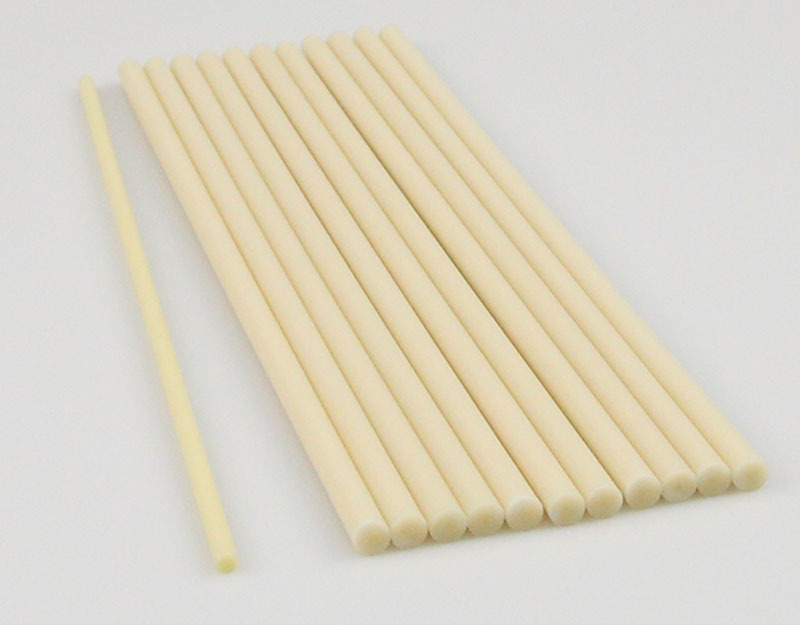

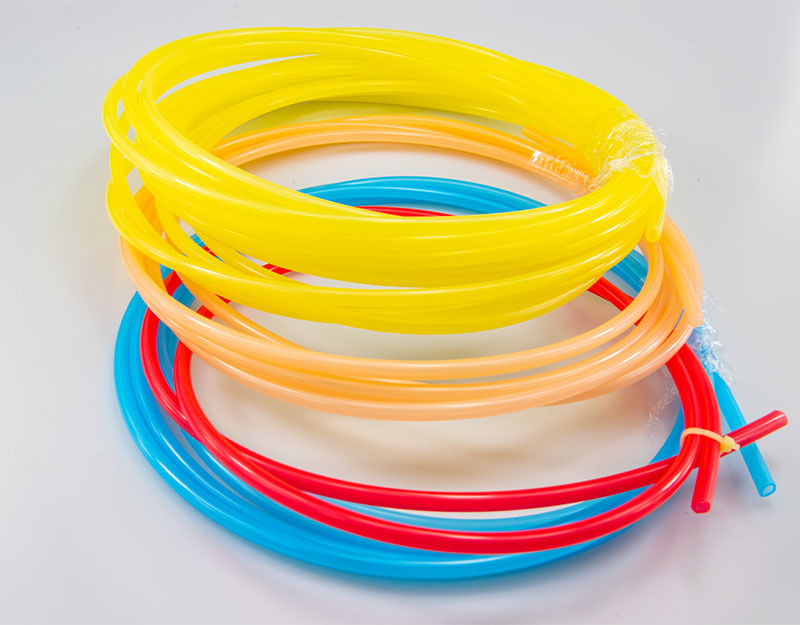

Fiber tube

Fiber tubes are high-performance protective sleeves made from a composite of high-strength fiber materials and thermoplastic resins. They are lightweight, high-temperature resistant, tensile resistant, and wear-resistant, and are widely used in automotive wiring harnesses, aerospace, industrial equipment, and robot cable protection.

Keywords:

Fiber tube

Category:

Hotline:

Email:

Fiber tube

Fiber tubing is a high-performance protective sheath made from a composite of high-strength fiber materials and thermoplastic resin. It features lightweight, high-temperature resistance, tensile strength, and wear resistance, and is widely used in automotive wiring harnesses, aerospace, industrial equipment, and robot cable protection.

Technical Parameters:

Rated Voltage: 1.2~4.0K

Rated Temperature: -60℃ to +200℃

Flame Retardancy: VW-1

Product Features:

Ultra-high strength: Fiber-reinforced structure, tensile strength is 3-5 times that of ordinary PVC pipes

High-temperature resistance: Long-term operating temperature -60℃~+200℃ (short-term up to 250℃)

Wear-resistant and corrosion-resistant: Suitable for harsh environments such as oil stains and chemical corrosion

Good flexibility: Bendable, adaptable to complex wiring needs

Application Range:

Silicone resin glass fiber tubing is made by weaving alkali-free glass fiber yarn into a tube and then coating it with silicone resin for high-temperature treatment. It has good dielectric properties, self-extinguishing properties, and flexibility, and is widely used in H&N grade motors, household appliances, electric heating equipment, special lamps, and internal wire bundles of televisions and electronic instruments for insulation protection.

Specifications

| Dimensions (mm) | Inner Diameter Tolerance (mm) | Average Wall Thickness (mm) | Length per Roll (m) |

| 0.8 | 0.8+0.2/-0.1 | 0.30±0.05 | 100 |

| 1.0 | 1.0+0.2/-0.1 | 0.30±0.05 | 100 |

| 1.5 | 1.5+0.2/-0.1 | 0.30±0.05 | 100 |

| 2.0 | 2.0+0.2/-0.1 | 0.30±0.05 | 100 |

| 2.5 | 2.5+0.2/-0.1 | 0.30±0.05 | 100 |

| 3.0 | 3.0+0.3/-0.1 | 0.30±0.05 | 100 |

| 3.5 | 3.5+0.3/-0.1 | 0.30±0.05 | 100 |

| 4.0 | 4.0+0.3/-0.1 | 0.40±0.05 | 100 |

| 4.5 | 4.5+0.3/-0.1 | 0.40±0.05 | 100 |

| 5.0 | 5.0+0.35/-0.15 | 0.40±0.05 | 100 |

| 5.5 | 5.5+0.35/-0.15 | 0.40±0.05 | 100 |

| 6.0 | 6.0+0.35/-0.15 | 0.40±0.05 | 100 |

| 7.0 | 7.0+0.35/-0.15 | 0.40±0.05 | 50 |

| 8.0 | 8.0+0.5/-0.2 | 0.40±0.05 | 50 |

| 9.0 | 9.0+0.5/-0.2 | 0.40±0.05 | 50 |

| 10.0 | 10.0+0.5/-0.2 | 0.50±0.05 | 50 |

| 11.0 | 11.0+0.6/-0.3 | 0.50±0.05 | 50 |

| 12.0 | 12.0+0.6/-0.3 | 0.50±0.05 | 50 |

Standard Colors: White, Red, Black, Brown

Custom specifications and colors are available upon request

Previous Page

None

Next Page

Related Products

Consultation

Leave your contact information and we will contact you as soon as possible