Corrugated tube

Corrugated tubes are cylindrical thin-walled corrugated shells with multiple transverse corrugations, widely used in media transmission, power wiring, machine tools, home appliances and other fields. Our company mainly produces PP and PA corrugated tubes, using advanced extrusion molding technology, combined with precise mold design, to ensure that the shape, size and performance of the corrugated tubes meet customer requirements.

Keywords:

Corrugated tube

Category:

Hotline:

Email:

Corrugated tube

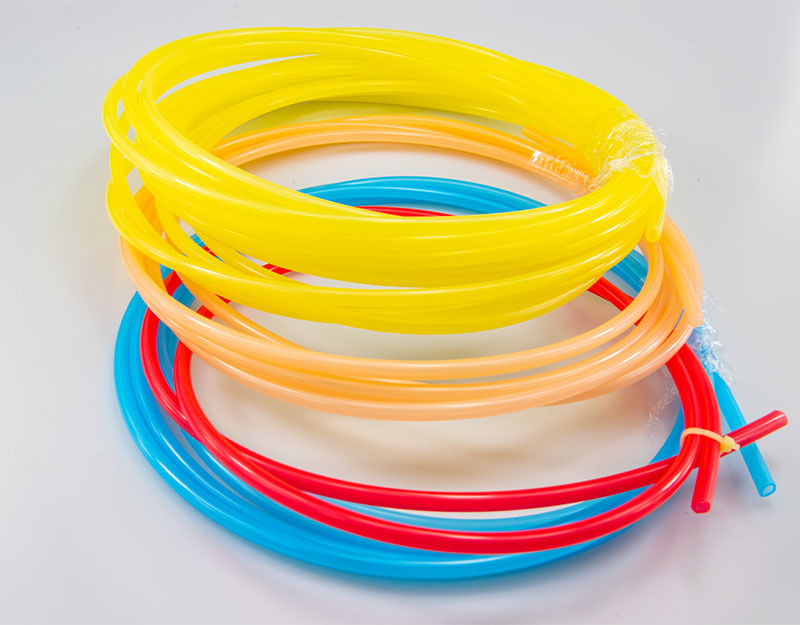

Corrugated tubes are cylindrical, thin-walled, corrugated shells with multiple transverse corrugations, widely used in media transmission, power wiring, machine tools, home appliances, and other fields. Our company mainly produces corrugated tubes in two materials, PP and PA, using advanced extrusion molding technology combined with precise mold design to ensure that the shape, size, and performance of the corrugated tubes meet customer requirements.

PP Flame-Retardant Corrugated Tube:

Temperature range: -40℃-+125℃ Color: Black (standard), orange, gray, red, blue, yellow, etc., can be customized according to customer samples.

Application fields: Automotive wire harnesses, machine tools, mechanical engineering, shipbuilding, communication lines, power engineering, and industrial automation, etc.

Flame retardant grade: QC/T29106-2014

Product characteristics:

Corrosion-resistant, abrasion-resistant, good flexibility, good flame retardancy, environmentally friendly and energy-saving, lightweight and high-strength

Uses: Suitable for the protection of wires and cables, preventing mechanical damage and external environmental corrosion.

Used for the protection of automotive wire harnesses, air conditioning pipes, fuel pipes, etc., to improve safety and durability.

In the fields of construction, agricultural irrigation, and water conservancy projects, it is used as a water and gas pipeline.

PA Nylon Corrugated Tube:

Temperature range: -40℃-+150℃

Color: Black (standard), orange, gray, red, blue, yellow, etc., can be customized according to customer samples.

High mechanical load-bearing capacity, good flexibility, and anti-twisting,

Application fields: Automotive wire harnesses, machine tools, mechanical engineering, shipbuilding, communication lines, power engineering, electronics and electrical appliances, rail transit, and industrial automation, etc.

Flame retardant grade: QC/T29106-2014

Product characteristics:

High-strength wear resistance, excellent temperature resistance, good electrical insulation, strong anti-aging performance, corrosion resistance, and abrasion resistance

Uses: Suitable for the transmission of liquids or gases in high-pressure and high-temperature environments, such as automotive braking systems and hydraulic systems. In electrical engineering, it is used as a protective tube for electrical lines. Used for the protection of precision instruments to prevent vibration and impact from damaging the instruments.

Specifications:

PA nylon flame-retardant, PP flame-retardant, open/closed corrugated tube

| Specifications (mm) | Inner diameter (mm) | Outer diameter (mm) | Wall thickness (mm) | Minimum bending radius | Packaging standard (M) |

| Φ5 | 5.2±0.4 | 7.6±0.4 | 0.20±0.07 | 5 | 400 |

| Φ6 | 6.0±0.4 | 9.0±0.4 | 0.27±0.1 | 8 | 400 |

| Φ7 | 7.4±0.4 | 10.2±0.4 | 0.27±0.1 | 10 | 200 |

| Φ8.5 | 8.5±0.4 | 11.5±0.4 | 0.27±0.1 | 10 | 200 |

| Φ10 | 10.0±0.4 | 13.0±0.4 | 0.27±0.1 | 20 | 200 |

| Φ11 | 10.7±0.4 | 14.1±0.4 | 0.27±0.1 | 25 | 200 |

| Φ12 | 12.0±0.4 | 15.8±0.4 | 0.27±0.1 | 30 | 200 |

| Φ13 | 13.2±0.4 | 17.5±0.4 | 0.27±0.1 | 35 | 200 |

| Φ14 | 14.3±0.4 | 18.5±0.4 | 0.27±0.1 | 40 | 200 |

| Φ15 | 15.2±0.4 | 19.5±0.4 | 0.27±0.1 | 40 | 200 |

| Φ17 | 17.3±0.4 | 21.7±0.4 | 0.27±0.1 | 45 | 100 |

| Φ19 | 19.5±0.4 | 23.8±0.4 | 0.27±0.1 | 45 | 100 |

| Φ20 | 20.5±0.4 | 25.0±0.4 | 0.30±0.1 | 50 | 100 |

| Φ22 | 22.1±0.4 | 27.0±0.4 | 0.30±0.1 | 55 | 100 |

| Φ25 | 25.0±0.4 | 30.0±0.5 | 0.35±0.1 | 55 | 100 |

| Φ28 | 28.2±0.4 | 34.0±0.5 | 0.35±0.1 | 60 | 50 |

| Φ32 | 32.2±0.4 | 38.0±0.5 | 0.35±0.1 | 60 | 50 |

| Φ36 | 36.0±0.4 | 42.5±0.5 | - | 70 | 25 |

| Φ48 | 48.0±0.4 | 54.5±0.5 | - | 80 | 25 |

Previous Page

None

Next Page

Related Products

Consultation

Leave your contact information and we will contact you as soon as possible