UL-PVC Conduit

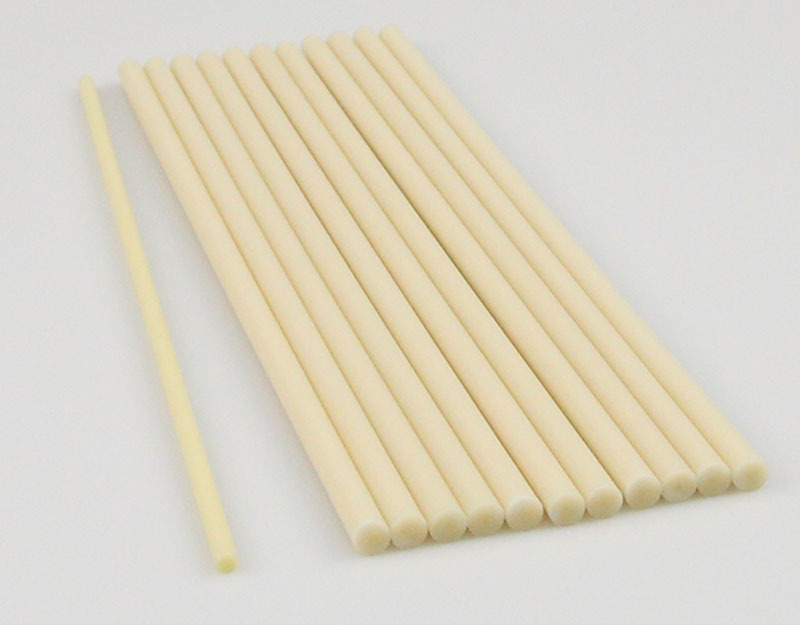

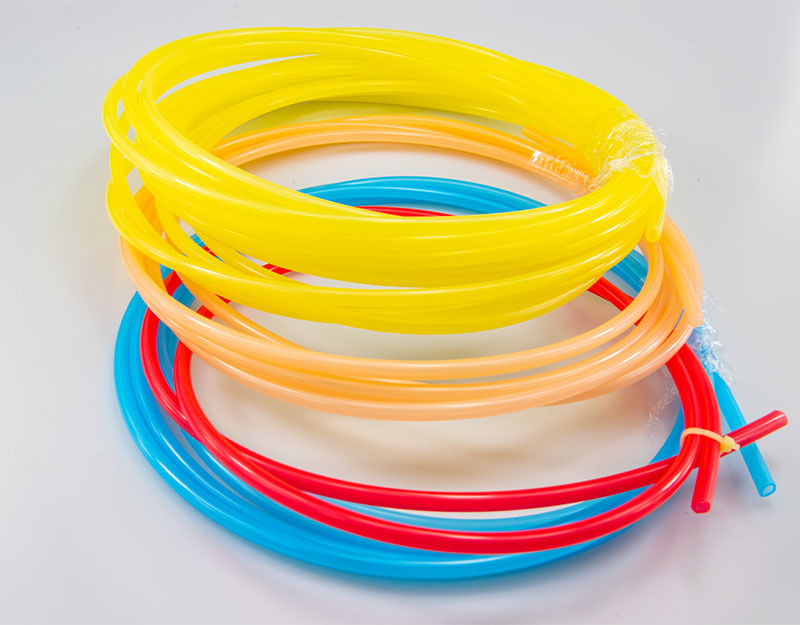

PVC tubing is mainly used as a soft, flame-retardant, non-shrinking tubing, widely used in electronics, home appliances, automobiles, machinery, toys, motors, and transformers. It has good electrical and physical properties and can effectively protect wires and cables from external environmental damage, ensuring stable transmission of current or signals. At the same time, PVC tubing also has acid resistance, corrosion resistance, and excellent flame-retardant properties, which can prevent the spread of fire to a certain extent and ensure the safety of equipment and personnel. Our company's PVC tubing has passed UL 110℃ certification, is environmentally friendly and complies with EU toy standards, and has ROHS REACH certification. It is widely used in products in the fields of electronic components, home appliances, automobiles, machinery, toys, motors, and transformers.

Keywords:

UL-PVC Conduit

Category:

Hotline:

Email:

UL-PVC Conduit

PVC tubing is primarily used as a soft, flame-retardant, non-shrinking tubing, widely applied in electronics, home appliances, automobiles, machinery, toys, motors, and transformers. It boasts excellent electrical and physical properties, effectively protecting wires and cables from external environmental damage and ensuring stable current or signal transmission. Simultaneously, PVC tubing possesses acid and corrosion resistance, as well as superior flame-retardant properties, preventing fire spread to a certain extent and safeguarding equipment and personnel. Our PVC tubing is UL 110℃ certified, environmentally friendly and compliant with EU toy standards, and holds ROHS and REACH certifications. It is widely used in electronic components, home appliances, automobiles, machinery, toys, motors, and transformers.

Characteristics

| Item | Performance Indicators | |

| Continuous Operating Temperature Range | -30~105℃ | |

| Tensile Strength (Mpa) | ≥10.4 | |

| Elongation at Break (%) | ≥100 | |

| Flame Retardancy | VW-1 | |

| Air Oven Aging | (136.0±1.0)℃ 7 days; 7 days at 136±1.0℃ | |

| After Aging | Tensile Strength (Mpa) | ≥7.28 |

| Elongation at Break (%) | ≥7.0 | |

| Voltage Rating (V) | 300V, 600V | |

| Breakdown Voltage (V) | ≥2500 (60 seconds) | |

| Bare Copper Corrosion | No Corrosion | |

| Thermal Shock | No Cracks | |

| Cold Bending | No Cracks | |

| Maximum Axial Change | ±10% | |

Standard Dimensions

| Standard Dimensions | Inner Diameter (mm) | Wall Thickness (mm) (300V) | Wall Thickness (mm) (600V) | Packaging Dimensions (m/Fl) |

| 21 | 0.79±0.1 | 0.35±0.05 | 0.40±0.05 | 305 |

| 20 | 0.86±0.1 | 0.40±0.05 | 0.50±0.05 | 305 |

| 19 | 0.96±0.1 | 0.40±0.05 | 0.50±0.05 | 305 |

| 18 | 1.07±0.1 | 0.40±0.05 | 0.50±0.05 | 305 |

| 17 | 1.19±0.1 | 0.40±0.05 | 0.65±0.05 | 305 |

| 16 | 1.34±0.1 | 0.40±0.05 | 0.65±0.05 | 305 |

| 15 | 1.50±0.2 | 0.40±0.05 | 0.65±0.05 | 305 |

| 14 | 1.68±0.2 | 0.40±0.05 | 0.65±0.05 | 305 |

| 13 | 1.93±0.2 | 0.40±0.05 | 0.65±0.05 | 305 |

| 12 | 2.16±0.2 | 0.40±0.05 | 0.65±0.05 | 305 |

| 11 | 2.41±0.2 | 0.40±0.05 | 0.65±0.05 | 305 |

| 10 | 2.69±0.2 | 0.40±0.05 | 0.65±0.05 | 305 |

| 9 | 3.00±0.3 | 0.50±0.05 | 0.65±0.05 | 305 |

| 8 | 3.38±0.3 | 0.50±0.05 | 0.65±0.05 | 305 |

| 7 | 3.76±0.3 | 0.50±0.05 | 0.65±0.05 | 305 |

| 6 | 4.22±0.3 | 0.50±0.05 | 0.65±0.05 | 305 |

| 5 | 4.72±0.3 | 0.50±0.05 | 0.65±0.05 | 305 |

| 4 | 5.28±0.3 | 0.50±0.05 | 0.65±0.05 | 305 |

| 3 | 5.94±0.3 | 0.50±0.05 | 0.65±0.05 | 305 |

| 2 | 6.68±0.3 | 0.50±0.05 | 0.65±0.05 | 152 |

| 1 | 7.47±0.3 | 0.50±0.05 | 0.65±0.05 | 152 |

| 0 | 8.38±0.3 | 0.50±0.05 | 0.65±0.05 | 152 |

| 5/16inches | 7.92±0.4 | 0.50±0.05 | 0.65±0.05 | 152 |

| 3/8 | 9.53±0.4 | 0.65±0.05 | 0.65±0.05 | 152 |

| 7/16 | 11.10±0.5 | 0.65±0.05 | 0.65±0.05 | 152 |

| 1/2 | 12.70±0.5 | 0.65±0.05 | 0.65±0.05 | 100 |

| 9/16 | 14.30±0.5 | 0.75±0.05 | 0.75±0.05 | 100 |

| 5/8 | 15.90±0.5 | 0.75±0.05 | 0.75±0.05 | 50 |

| 3/4 | 19.10±0.7 | 0.85±0.05 | 0.85±0.05 | 50 |

| 7/8 | 22.20±0.7 | 0.85±0.05 | 0.85±0.05 | 50 |

Previous Page

None

Next Page

Related Products

Consultation

Leave your contact information and we will contact you as soon as possible